The Future of Supply Chains in Asia: Building Resilience Through Automation and Innovation

Asian supply chains are entering a new era, as global trade grows, and pressure mounts to become faster, smarter, and more resilient. In this environment, supply chain leaders must go beyond traditional models and embrace digital transformation to gain an advantage over the competition.

The Asia Pacific region is responsible for almost half of global manufacturing, and the Association of Southeast Asian Nations (ASEAN) is forecast to become the next global manufacturing hub – establishing itself as a strategic region in worldwide supply chain networks.

ASEAN is a regional intergovernmental organisation comprising 10 countries: Brunei, Cambodia, Indonesia, Laos, Malaysia, Myanmar, the Philippines, Singapore, Thailand, and Vietnam.

In 2023, these nations received a combined US$230 billion in foreign direct investment (FDI), despite the world economy’s overall decline. This influx signals a fundamental shift as companies diversify their supply chains and establish new production corridors throughout Southeast Asia. The change presents opportunities for businesses to modernise their supply chain operations with advanced logistics and automation technologies.

Dematic SVP – President Asia, China, and MEA, Steve Cheung, says businesses must embrace supply chain innovation before they are left behind.

"Our business exists to optimise supply chain efficiency and reduce delivery lead times utilising smart automation solutions," he says.

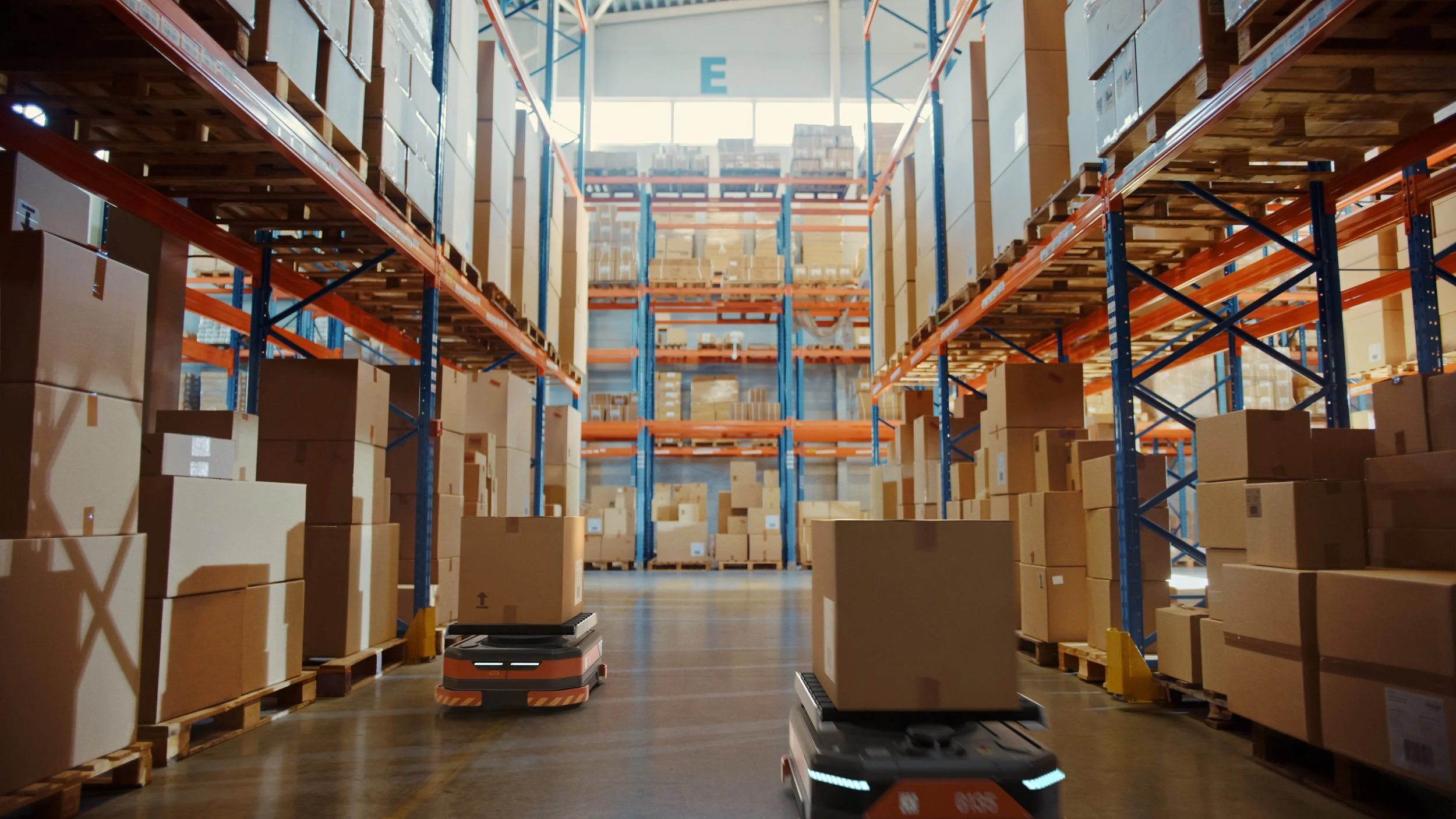

"We see more and more companies investing in robotics and automated systems, as it gives them the agility required to adapt their supply chains, handle diverse product ranges, and respond to market demands more quickly and effectively at a fraction of traditional costs. Companies that don't modernise their supply chain infrastructure risk being left behind in an increasingly connected global marketplace."

Investment in the Region

On top of the significant FDI into ASEAN, the region's supply chain infrastructure also saw greenfield investment project announcements double in 2023 (ASEAN). This signals robust expansion of logistics networks, distribution centres, and manufacturing facilities that will reshape global supply chain geography over the coming decade and beyond.

To support this supply chain transformation, Dematic has recently expanded its Asian footprint with a new facility in Jinan, China. The new plant manufactures automated logistics products and develops cutting-edge supply chain solutions, with an annual capacity of up to 500 Automated Storage & Retrieval (AS/RS) cranes and conveyor systems designed to optimise goods movement and warehouse operations across the region's evolving distribution networks.

“I championed the new Jinan facility because it enables us to build supply chain resilience by manufacturing closer to our APAC customers. The COVID pandemic was a wake-up call when transportation costs from Europe and the U.S. surged five to six times higher," Steve says.

"Our Jinan investment has proven essential as trade tensions and geopolitical disruptions persist. These challenges highlight why APAC manufacturers need agile supply chains and partners who can deliver solutions locally, reducing dependency on long-distance logistics.”

Automation and Flexibility

As stated in an Accenture’s report, Rethinking the course to manufacturing’s future, “By 2040, the most advanced factories won’t be managed – they will be orchestrated.”

The report surveyed hundreds of factory managers from around the world and found that 51% saw ‘Completely automated warehouses’ as likely or very likely to be implemented by 2040. Similarly, 52% expected the same of Gen AI-based self-learning machines.

Steve states that AI is more than a passing trend, and that Dematic is poised to enable the advancement of manufacturing and supply chains in the region.

“Some technologies are popular because they’re novel and different, but AI and automation are truly becoming the new way of logistics,” he says.

“Dematic is excited to optimise more customer facilities over the coming years, as more businesses recognise the potential of automation. Once our solutions are implemented, our customers see near-instant benefits of faster decision-making, more accurate data, greater productivity, as well as operational resilience and flexibility.”

Dematic’s solutions include logistics automation for pallet, case, and eaches picking and storage, as well sortation, engineering, warehouse software, and advanced computer modelling – all backed by a 24/7 support team.

Case Study: Dematic & Alibaba

One prominent player in the Chinese multinational online marketplace is Alibaba. In 2021, as the region continued to recover from the pandemic, Dematic was selected by Alibaba Group’s flagship platform in Southeast Asia, Lazada, to scale up its operations and meet growing customer demand with advanced automation solutions.

Lazada’s grocery arm and Singapore’s biggest online grocery platform, RedMart, offers over 100,000 products to Singaporeans, and its West Fulfilment Centre in Singapore required much smarter technology.

“Initially, their delivery times took a few days, and with our automated system we cut it down to a few hours. This was a good example of how we served not only the customer but also helped people to improve their lives during COVID times,” Steve says.

The Dematic automated solution includes robotic shuttles, ergonomic high-speed pick stations, an intelligent conveying system, and a new sortation system, all managed by a smart software platform to improve processes for pickers, packers, and management staff.

With Dematic’s help, RedMart staff have increased their picking productivity by 500%, and fulfilment times have been greatly reduced, presenting a perfect example of automation and robotics in action for ASEAN businesses.

It’s now up to similar businesses to realise the potential of these intelligent solutions and include them in business strategies going forward.

For more information, visit https://www.dematic.com/en-au/