Origin Backs Battery Startup: Q&A with Professor Thomas Nann on Allegro Energy’s Innovation

Australia is investing heavily in clean energy, but as coal is phased out, storing renewable power at scale remains a major challenge. So far, lithium batteries have dominated so far, yet they’re expensive, supply-constrained, fire-prone, and difficult to recycle.

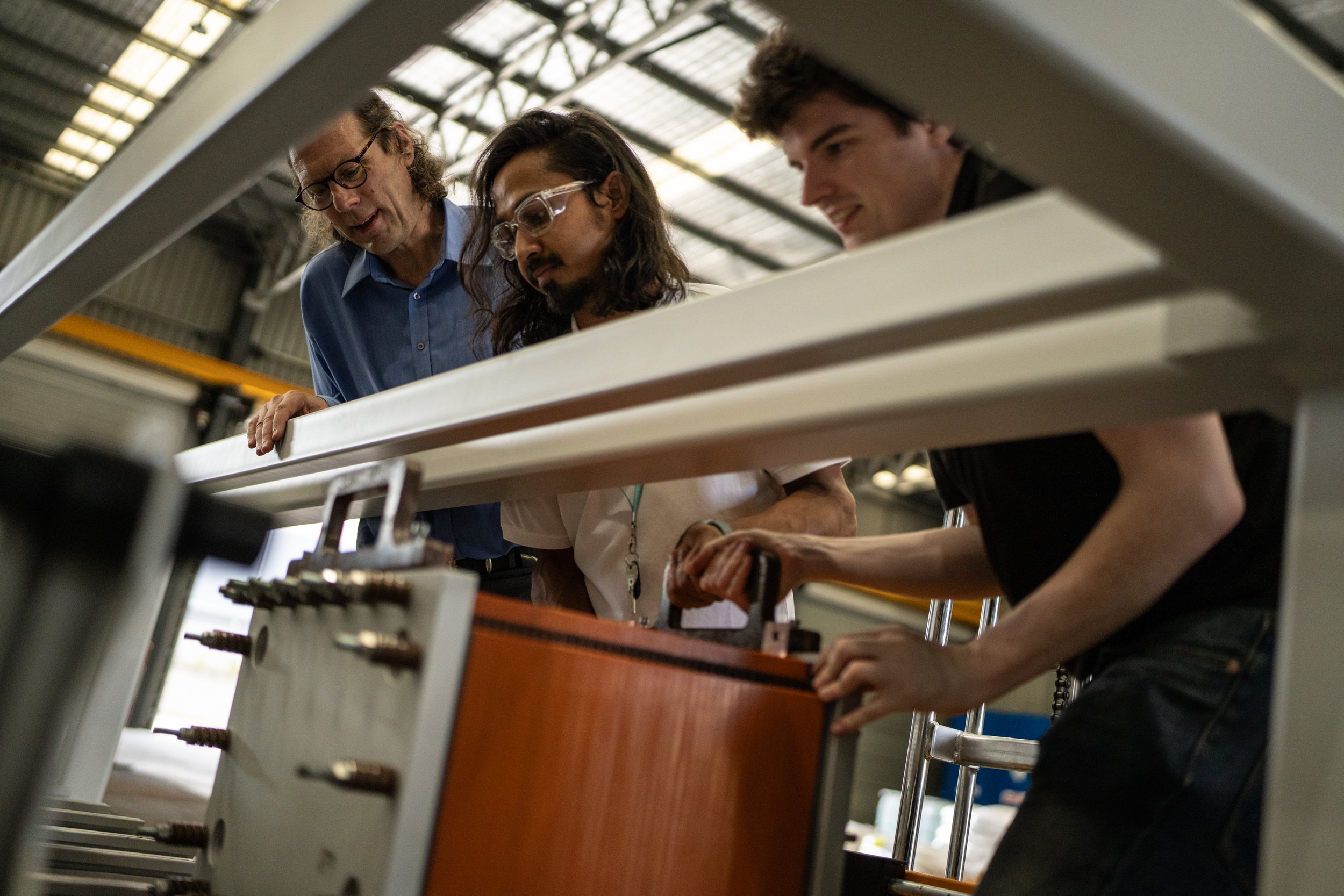

Allegro Energy, a Newcastle-based startup backed by Origin Energy, is taking a different path. The company has developed the world’s first water-based battery electrolyte – non-flammable, fully recyclable, and much cheaper than lithium – and is already piloting the technology at Origin’s Eraring Power Station with an 800 kWh storage plant.

It’s a home-grown solution with global potential, one that could create local jobs, strengthen clean energy supply chains, and reduce reliance on imported minerals. In this Q&A, Professor Thomas Nann, CEO and Co-Founder of Allegro Energy, discusses what the innovation means for Australia’s energy future.

1. Allegro Energy has developed the world’s first water-based battery electrolyte. From a supply chain perspective, how does this innovation change the need for scarce and imported materials like lithium, cobalt, and nickel?

One of the biggest advantages of our technology is that it removes the need for scarce, mined minerals like lithium, cobalt, or nickel altogether. These materials are expensive, geographically concentrated, and subject to volatile global markets and geo-political risk. Our water-based electrolyte relies on abundant ingredients that can be sourced at scale, and at a fraction of the cost. That fundamentally shifts the economics of energy storage because we’re no longer tied to fragile, high-risk supply chains, and that creates a lot of resilience for countries like Australia.

Professor Thomas Nann, CEO & Co-Founder of Allegro Energy

2. Traditional battery supply chains are highly globalised and complex. How does Allegro’s approach simplify or localise the supply chain for renewable energy storage, and what opportunities does this create for Australian manufacturing?

Today’s lithium supply chains stretch across multiple continents – minerals mined in one country, refined in another, manufactured in a third, and shipped globally. That complexity creates bottlenecks and vulnerability. Our approach is the opposite. Our water-based batteries can be produced with readily available materials, using manufacturing processes that can be built here in Australia. That opens the door to a more secure clean energy supply chain, one where Australia can become a key clean technology manufacturer, creating skilled jobs and securing local control over critical energy infrastructure.

3. Recycling and end-of-life management are major challenges in energy storage. Can you explain how Allegro’s water-based batteries address recyclability, and what this means for building more circular, resilient supply chains?

Traditional lithium batteries are expensive, supply-constrained, fire-prone, and difficult to recycle. In contrast, our batteries are non-flammable, far cheaper than lithium, and fully recyclable; with the materials recovered and fed straight back into new batteries. That means end-of-life is no longer a liability but an opportunity to recapture value, reduce waste, and build a genuinely circular battery supply chain.

4. You’re piloting this technology at Origin’s Eraring Power Station. What lessons from this deployment are most relevant to scaling the technology, and how could it help repurpose coal infrastructure for clean energy storage?

The Eraring project is giving us more critical insights into how our technology performs at grid scale, under real-world conditions typical of the global transition to a clean energy infrastructure and away from a coal-fired one. The biggest lesson so far is that coal sites can be repurposed rather than retired. The transmission infrastructure, the land, and the grid connection are already there, and our batteries are well suited to providing the long-duration storage that’s needed to turn those assets into renewable energy hubs. It’s a model that could be replicated across Australia and internationally, transforming the legacy of coal into the backbone of a clean energy system, and we’re very pleased to see it already in action in Australia.

5. Looking ahead, what role do you see for Australia in the global battery supply chain? Could home-grown technologies like Allegro’s give Australia a stronger position beyond being a raw materials exporter?

Absolutely. For too long, Australia’s role in energy storage has been limited to digging minerals out of the ground and sending them overseas. With technologies like ours, Australia has the chance to flip that script – to be a global leader in innovation, manufacturing, and deployment. We can export batteries, not just minerals. That means capturing more value at home, strengthening our own energy security, and positioning Australia as a clean energy technology powerhouse on the global stage.