CoolDrive Accelerates Supply Chain Modernisation with Dematic AutoStore System

Global leader in supply chain automation, Dematic, has been selected by CoolDrive Auto Parts, one of Australasia’s leading automotive parts distributors, to deliver a high-performance intralogistics solution for its new greenfield distribution centre. The project, developed in partnership with ThreeSixty Supply Chain Group, will consolidate CoolDrive’s three existing Victorian sites into a single, advanced facility powered by Dematic’s Goods-to-Person (GTP) automation and conveyor sortation.

CoolDrive’s decision to invest in automation was driven by more than a decade of rapid growth and rising inventory complexity, with spare parts requiring the management of thousands of unique stock keeping units (SKUs) across multiple categories. To keep up with demand, the company had acquired additional storage sites to house growing volumes of bulk stock, resulting in fragmented operations, multiple handling steps, and inefficiencies across its fulfilment processes. With stock volumes continuing to rise, CoolDrive recognised the need for smarter, consolidated infrastructure that could scale efficiently and sustainably.

“CoolDrive has grown considerably in recent years and needed a supply chain solution that could keep pace,” said Tim Blanchard, COO of CoolDrive Auto Parts. “This new facility is a major step forward in our commitment to delivering fast, accurate, and efficient service to our customers. Dematic’s deep operational understanding and experience integrating with different platforms made them a natural fit for the project.”

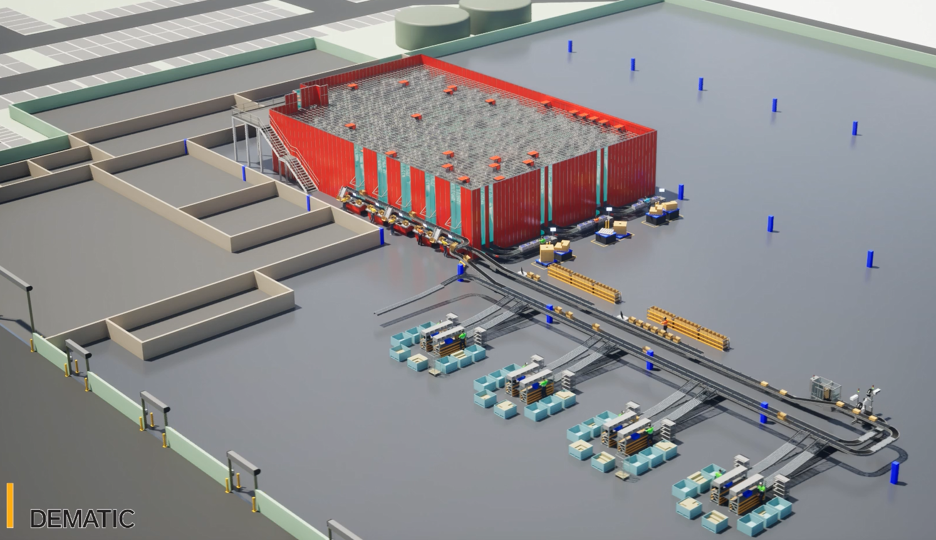

The solution is built around Dematic’s AutoStore system, a proven technology known for its space-saving design and operational efficiency. The automation will streamline CoolDrive’s split case picking operations and final order sortation, reducing manual handling, optimising workflows, and setting the foundation for scalable future growth.

The Dematic system will provide CoolDrive with a number of strategic advantages, including a reduced warehouse footprint, improved labour efficiency, and greater resilience in meeting peak demand. It will also enable the business to expand its storage and throughput capacity in modular phases, giving the team flexibility to adapt to future needs without major disruption.

The solution, which integrates seamlessly with CoolDrive’s warehouse management system (WMS), was informed by Dematic’s proven success implementing a similar automated GTP system for another Australian spare parts distributor operating the same Warehouse Management System (WMS) Host, helping to accelerate deployment and reduce implementation risk.

“We are proud to partner with CoolDrive on this exciting project,” said Terry Jamieson, Business Development Manager at Dematic. “AutoStore is a powerful platform for businesses dealing with high SKU volumes, and our experience across similar applications in the region has shown that it delivers real, measurable value. This solution will give CoolDrive the operational agility they need to continue leading in a competitive market.”

The new facility will position CoolDrive for long-term success, providing the automation capabilities to meet growing customer expectations while supporting a more sustainable, efficient supply chain. The facility is scheduled to be completed by August, 2026.

For more information about Dematic, visit dematic.com or follow us on LinkedIn, Facebook, and Instagram.